When you grow out of your favorite pair of shoes, you’re left with two options. You can either one, keep wearing them and force your feet to stay the same size forever, or two, get a new pair. And if you have normal-sized feet, you most likely went with the second option. We did too!

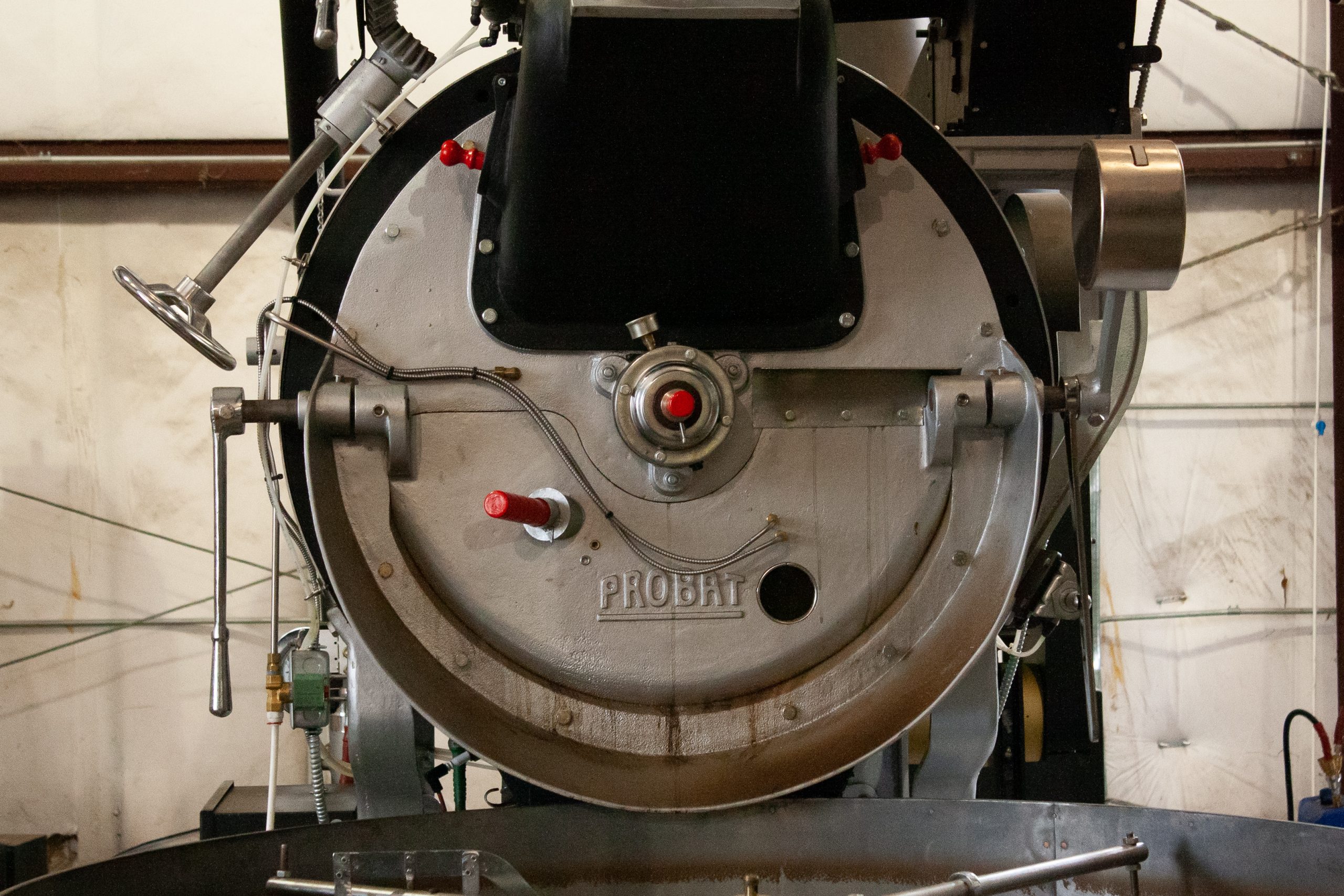

Regrettably, that was a metaphor and no one received new shoes. However, we did purchase a new coffee roaster! Over the past few years, more and more people have been joining us for coffee, which means we’ve had to step up our game. To give you an idea, in our 2017 holiday season we made about 2,800 bags of Snowflake Crunch (our most popular coffee flavor). This year we’re projecting that number to be around 4,000 bags. If we made no changes in response to that type of demand, roasting more would require increased hours, additional hands, and result in an increasingly hot warehouse. Since that’s not ideal, we decided to get a new pair of shoes. Meet our newest hire, the Probat G60.

“So what’s ‘G60’ about it?”

“60 kilograms. That’s how much it can roast at once. And the ‘G’ is just the model type.” Joe, our lead roaster replied.

To give you an idea of how big that is, our other roasters are 15 kg and 30 kg, so it’s double the capacity of our previous heavy-hitter. This thing came in on its own semi-truck and took about eight weeks to assemble. Make no mistake, this thing is a beast.

“Neat. So tell me a little about it. How does it work?”

“Well, there’s basically two styles of roasting, and we use gas-fired drum roasters. That means the coffee is roasted mainly by convection from a burner under the drum. That heated air is then pulled through the drum, roasting all the coffee evenly.”

“So how much coffee are we talking about?”

“60 kilograms is about 132 lbs. Depending on the coffee, we can roast about that much per batch. Moisture-dense coffees roast better with smaller batch sizes, so depending on the coffee region’s climate, altitude, and processing methods, we may decide to roast more or less at one time.”

“How many bags of coffee does that translate to over the course of the entire day?”

“Well, if we really pushed it, we could roast about 3,000 lbs of coffee in a day if we used all three roasters. That’s a serious work day though.”

“That seems like too much power for one man.”

“Well,” as he shrugged.

“It sounds like this will definitely come in handy with the holidays coming up.”

“Absolutely. It changes production time completely. We’ll go from having to spend a full day roasting Billy Goat to knocking that out in just a couple of hours. It basically cuts the production time in half, allowing us to focus on other areas like maintenance and sourcing new coffees. Plus it allows our staff to relax a little bit.”

“Speaking of relaxing a little bit, how has the new roaster changed your job other than giving you more time to get interviewed about it?”

“I read more emails now?” We both chuckled (frankly because that’s not true).

He continued. “It allows me to take part in the quality control I never had time to before. Cupping, visiting other cafés, calibrating brewers, and figuring out which coffees are selling so I can adjust accordingly. Maybe being less behind the scenes? I’m not sure, but it lets me focus on improving roasting profiles.”

“That’s cool. So while the decreased production time might not always affect our customers, the quality of our coffee definitely will.”

“Exactly. Less stress.”

“Why doesn’t everyone have a roaster this big?”

“More people do than you might think. This is actually a pretty average size for a regional wholesale coffee roaster. They can get up to 500 kilograms.”

“How many semi-trucks would you need to move that and why didn’t we get one?”

“Things become increasingly complicated beyond 60 kilograms. You start needing processes like quenching systems, additional space, even, as odd as it may sound, storage bins. Infrastructure becomes a huge part of the game once you start to scale. Plus, they become harder and harder to dial in roast profiles the larger you go. If you’re working with an expensive single origin, it’s possible to waste more product trying to decide what tastes best on a large roaster compared to a smaller one. Using a smaller roaster allows you to run smaller test batches resulting in less wasted product.”

“Interesting. So, the decision to stay at 60 kilograms was for quality.”

“Pretty much.”

“Last question. Have you named it?”

“No.”

“Why?”

“I don’t want to.”

“It just seems like a creative writing major would have—”

“—named it?”

“Yeah…”

“Well, I just called the previous two red and blue. I guess I’m not a romantic like that.”

We both chuckled (frankly because that was also not true).